IN-HOUSE ENGINEERING

Work Flow

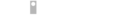

Feasibility Study

- Stowage plan

- Stability & Structural analysis

- Motion analysis

- Vessel reinforcement study

Transport Engineering

- Voyage plan

- Intact & Damage stability

- Local & Global strength analysis

- Grillage & Seafastening design

Software

Patran/Nastran, X-Mesher, Patran-Pre, AutoCAD, Sestra, SACS, GeniE and more

Loading

- Ballast plan for load out

- Mooring plan for load out

- Grillage installation

- Loading supervisor

Software

NAPA, GHS, Cyloader, Optimoor, HydroD Stab., X-tract, Auto Tide and more

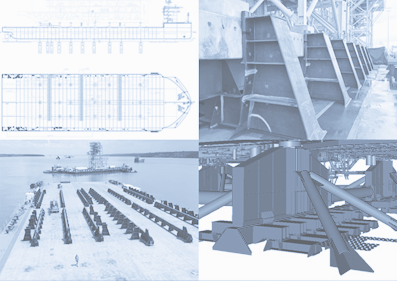

Voyage Monitoring

- Cargo safety

- Transport route

- Motion amplitude

- Weather evaluation

Software

Octopus onboard, Octopus online, Octopus office, MOSES, Postresp and more

Discharging

- Ballast plan for load in

- Mooring plan for load in

- Grillage remove

- Discharging supervisor

Software

NAPA, GHS, Cyloader, Optimoor, HydroD Stab., X-tract, Auto Tide and more

Engineering Capability

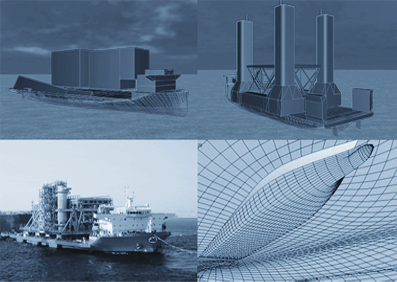

Feasibility Study

- Provide our clients with the suitable vessel

- To meet clients demand;

- Stowage optimization

- Voyage condition

- Stability calculation

- Route analysis

- Vessel motion

- Strength check

- Cargo specification influences vessel selction, engineers carry out feasibility study such as stowage, voyage stability and motion analysis to demonstrate whether the cargo can be safely stowed on proposed vessel.

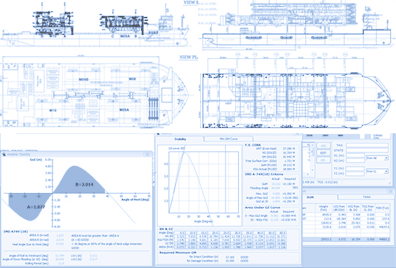

Grillage & Seafastening design

- Cost effective design and implementation

- Megaline is able to design all types of grillage and seafastenging to withstand the expected voyage acceleration.

- The concept design of the grillage and seafastening is done using cutting edge technology. In addition, use of existing material is prioritized or design optimization is implemented to be cost effective

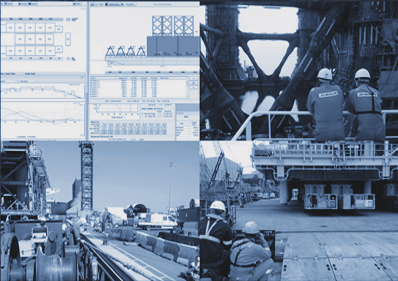

Voyage monitoring

- Vessel and cargo safety is of the utmost essential

- Megaline installed onboard motion sensors in order to ensure cargo safety. Route for any shipment is analyzed using Global Wave Statistics (GWS) database.

- Onboard vessel motion monitoring system allows our crew to anticipate expected motion based on the latest weather information and suggests alternative route.

- Megaline can access online system to follow up;

- Maximum roll and pitch amplitudeVoyage condition

- Acceleration at cargo COG

- Expected weather (wave) en-route

- Real time vessel position

- Comparison with design criteria

- If automated service is unavailable a set of critical motion curve is provided to the Master. This critical motion curve guides to maintain the rolling or pitching of the vessel within the maximum allowable limit of the cargo.

Transport engineering

- Providing solutions to safe voyage

- Megaline will utilize different types of marine spread to ensure that the cargoes are transported in the most efficient way possible. The design is optimized in a way to give maximum support at minimum cost.

- The modeling is done based on the preliminary design to check every aspects of transportation. The vessel strength will be checked in multiple phases according to the weight spread of the cargo on vessel before loading.

- Voyage analysis for specific route with a design sea state criteria is carried out in order to receive the relevant marine warranty certificate to confirm the engineering outputs are in line with project guidelines.

Loading operation

- Proper mothod for safe execution

- Loading and discharging methods;

- Roll on & off

- Lift on & off

- Skid on & off

- Float on & off

- Megaline follows the correct procedures to ensure safe operation. Supervisors oversee cargo final weight for trailer movement, vessel heel condition during skidding and stability check for vessel submerging operation.

- Following engineering items are checked;

- Final weighing report

- Weather condition (wind, tide, swell etc.)

- Fender capacity and position

- Mooring line failure condition

- Above all, having good communication between site personnel is the key to success.

Rules

DNV-OS / DNV-RP

GL-Noble Denton

ISO 19901-6

KR

ABS

AISC

OCIMF

IMO